Solder Paste Jetting for Flex PCB Assembly

Solder Paste Jetting Overcomes a lot of the Solder Deposition Issues with Today’s Flex Circuit Assembly

At PICA we do a lot of Flex Circuit Assembly (FCA) for our valued Customers. They ask us to install 0201 and 0.35mm pitch components on FCAs. Here are a few of the challenges with solder deposition on FCAs.

- Flex Circuits can have shrink and to a lesser degree stretch from lot to lot.

- Flex Circuits often have stiffeners that are above the plane of the components.

- Some FCAs with 0201 and 0.35mm pitch components will have other larger components and connectors that depend on significant deposits of solder for mechanical strength.

The amount of shrink associated with Flex Circuits becomes an issue when dealing with 0201 and 0.4mm and below pitch components. A solder paste stencil cannot shrink and stretch to match up with the Flex. Our MY600JX Solder Paste Jetter looks at features on the Flex such as fiducials or component pads and shrinks or stretches the program to match the circuit. This capability is essential when processing FCAs that have an area of 18mm square with 327 Opportunities for a Defect.

It is common for Flex Circuits to have stiffeners in locations that require a rigid support that are +Z to the plane of the circuit. If the stiffener is 0.5mm or less and components are not close to it, a solder paste stencil can work. With our Solder Paste Jetter, this becomes a non-issue. Z keep out areas are programmed in to insure the Print Head does not collide with the stiffener while still allowing very precise paste application near the stiffener.

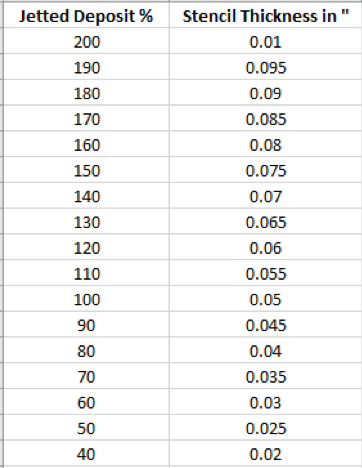

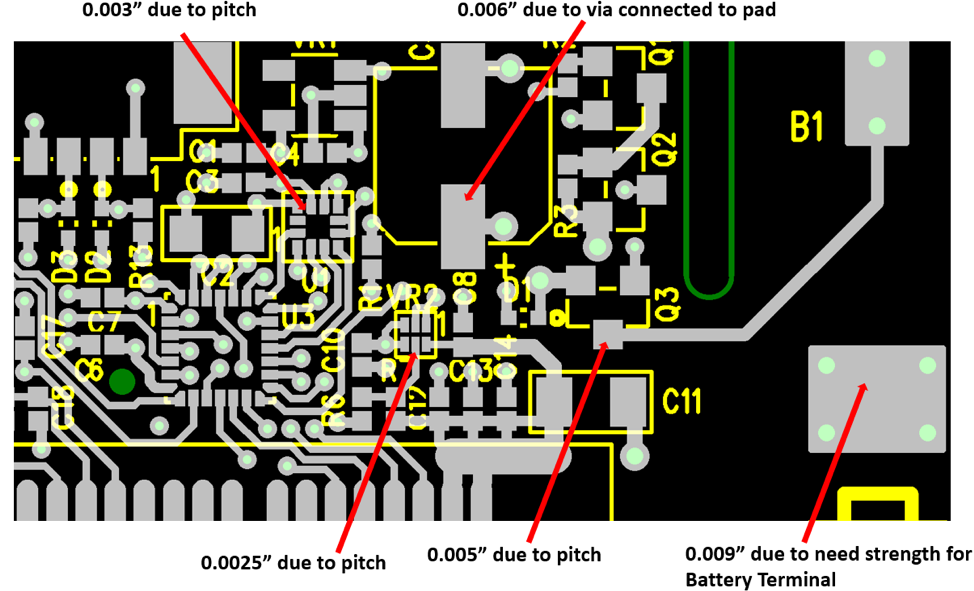

The FCAs of today often have very small and very fine pitch components intermixed with larger components. With the solder paste stencil approach it can be a challenge when you have components requiring a very precise and minute amount of solder deposition to avoid bridging, next to components requiring larger depositions for mechanical strength. Step-up or step-down stencils can be a solution on some designs if there is sufficient clearance between the base stencil and the step-up or step-down. Most of today’s designs do not allow this option. With our Solder Paste Jetter we can jet a pad at a 0.002” stencil equivalent right next to a pad with 0.01” stencil equivalent.

Here is an example of a FCA that is using the capability of Jetting various deposition percentages to have the effect of different stencil thicknesses.

PICA is increasingly seeing FCA’s that the traditional solder paste stencil process is not an option. Solder Paste Jetting has proven to be a very viable and reliable solution.